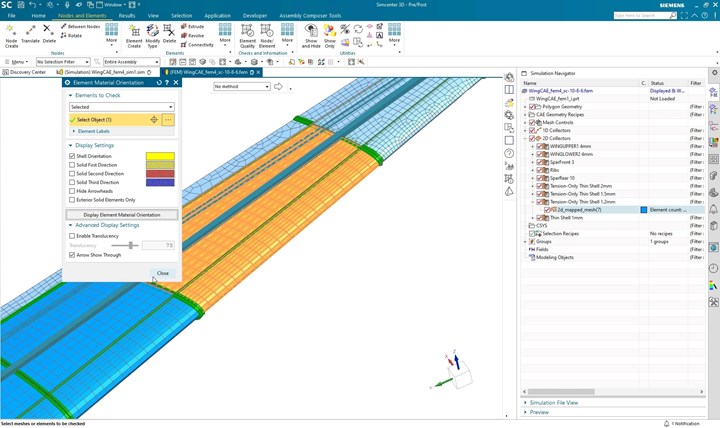

The stiffness of skinny structural panels in airframe buildings can improve based on no matter if the panels are in compression or rigidity. The new stress-only-quad ingredient can change the shells into shear panels if panels go into compression. Picture Credit score: Siemens Digital Industrie Software

The latest launch of Siemens Digital Industries Software’s (Plano, Texas, U.S.) Simcenter software for mechanical simulation can help streamline electrification engineering jobs, helps new aircraft meet margins of basic safety, simplifies longevity testing across several industries and substantially far more.

“Addressing complicated engineering worries these kinds of as building merchandise that are much more strong, nevertheless greener, lighter yet more powerful involves a completely-integrated CAE option,” Jean-Claude Ercolanelli, senior vice president, simulation and exam options, Siemens Electronic Industries Software package, states. “The latest launch of Simcenter features a host of potent enhancements to assistance engineers meet those people difficulties proficiently and drastically speedier than ever just before, no matter if that is getting tire get in touch with simulations solved 45{2c093b5d81185d1561e39fad83afc6c9d2e12fb4cca7fd1d7fb448d4d1554397} more rapidly or lowering airframe construction preprocessing by up to 80{2c093b5d81185d1561e39fad83afc6c9d2e12fb4cca7fd1d7fb448d4d1554397}.

In accordance to Siemens, highlights bring new performance to the Simcenter family of merchandise. Especially for the aerospace sector, new abilities reduce the number of products desired to simulate the behavior of skinny plane skins and perform margin of protection calculations more promptly than previous releases. In addition to the new enhanced airframe purposes, Simcenter can reportedly help engineers far better comprehend rocket launch dynamics by simulating the liquid sloshing in gas tanks.

A new capacity in Simcenter Nastran software program will help airframe engineers with thin-skinned airframe buildings that have various stiffness actions relying on the load circumstance tension (membrane) as opposed to compression (shear). These days, engineers usually make many types and qualities to account for all the distinctive loading disorders. Siemens claims the tension-only-quad will adjust from membrane behavior to shear conduct routinely so only a solitary design is required to depict an airframe framework — reducing simulation preprocessing time by up to 80{2c093b5d81185d1561e39fad83afc6c9d2e12fb4cca7fd1d7fb448d4d1554397}.

Read through: Best 10 CompositesWorld goods of 2022

Added updates correspond to additive producing (AM), automotive and industrial equipment, though Siemens suggests the highlights are applicable throughout all industries and workflows:

- Additive producing: Build system simulation and review simulation benefits right from distant simulations

- Automotive: Break down electrical automobile (EV) powertrain silos/enhance simulation apps, analyze wiper get hold of designs and update highway get in touch with algorithm

- Industrial equipment: Sturdiness prediction/analysis improvements, simulating magneostriction consequences, produce/estimate advanced rotor dynamic instances.

Pay a visit to this link for higher insight in Simcenter software performance.