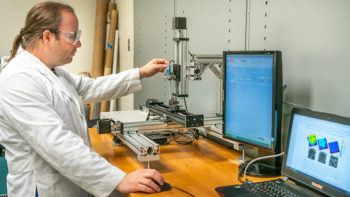

Daniel Salas demonstrates how the hidden magnetic tag can retail store a cache of info within an item.

Texas A&M Engineering

Making certain created goods and parts have not been copied and replaced illegally by counterfeited products is a high-precedence issue of the manufacturing and protection industries in the U.S. and close to the globe.

A potential option would maintain huge-achieving impacts and implications in different spots ranging from improving biomedical implants to guarding national protection assets.

Texas A&M College researchers have produced a strategy of imprinting a concealed magnetic tag, encoded with authentication data, inside of manufactured hardware through the component fabrication course of action. The innovative method retains the probable to expose counterfeit products much more conveniently by changing physical tags — these kinds of as barcodes or speedy reaction (QR) codes — with these concealed magnetic tags, which serve as permanent and exceptional identifiers.

The venture, titled “Embedded Facts in Additively Made Metals by way of Composition Gradients for Anti-Counterfeiting and Offer Chain Traceability,” is a faculty husband or wife undertaking supported by the SecureAmerica Institute. It includes researchers from the Office of Elements Science and Engineering and the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M. The workforce not too long ago revealed its investigate in the journal Additive Producing.

The school investigators on the undertaking include Ibrahim Karaman, Chevron Professor I and section head of the materials science and engineering office Raymundo Arroyave, professor of components science and engineering and Segers Loved ones Dean’s Excellence Professor and Richard Malak, associate professor of mechanical engineering and Gulf Oil/Thomas A. Dietz Occupation Improvement Professor. In addition to the college, Daniel Salas Mula, a researcher with the Texas A&M Engineering Experiment Station, and doctoral pupil Deniz Ebeperi — each customers of Karaman’s study team — have labored on the undertaking. The staff has also collaborated with Jitesh Panchal, professor of mechanical engineering at Purdue University.

Making certain safety and dependable authentication in producing is a vital countrywide problem, with the U.S. investing billions of pounds in production. Without this kind of a strategy readily accessible, it can be practically extremely hard to differentiate an authentic portion or ingredient from its counterfeit copy.

“The problem is that when I appear up with an concept, unit or section, it is pretty quick for other individuals to duplicate and even fabricate it much extra cheaply — nevertheless possibly at a lessen top quality,” Karaman reported. “Sometimes they even place the same model identify, so how do you make certain that product is not yours? (The embedded magnetic tag) provides us an possibility and a new instrument to make sure that we can shield our defense and production industries.”

The team’s customized a few-axis magnetic sensor is able of mapping the surface and revealing the areas exactly where an embedded magnetic tag is obtainable.

Texas A&M Engineering

The group is implementing metal additive manufacturing tactics to accomplish its intention of effectively embedding readable magnetic tags into metallic pieces with out compromising on general performance or longevity. Researchers applied 3D printing to embed these magnetic tags under the surface area into nonmagnetic steel hardware.

Other purposes for this technique involve traceability, high quality manage and far more, mostly dependent on the business in which it is used.

When embedded into a nonmagnetic merchandise, the magnetic tag is readable working with a magnetic sensor gadget — such as a smartphone — by scanning around the appropriate location on the merchandise, letting the specified details to be accessed by the user.

When other procedures exist for imprinting info, they principally demand advanced and costly gear that introduces a barrier to serious-environment implementation.

“Different methods have been applied to check out to regionally change the houses of the metals all through the manufacturing procedure to be equipped to codify details inside the component,” reported Salas Mula. “This is the 1st time that magnetic properties of the substance are getting used in this way to introduce information and facts within a nonmagnetic portion, especially for the 3D printing of metals.”

Ebeperi explained that to map the magnetic looking at of the aspect, the workforce designed a custom 3-axis magnetic sensor able of mapping the area and revealing the regions in which the embedded magnetic tag was accessible.

Although the program is much more protected than a bodily tag or code located on the exterior of an product, the team is nevertheless functioning to increase the complexity of the method’s stability.

As the project proceeds, Karaman claimed the subsequent ways consist of producing a much more secure approach of studying the information and facts, perhaps by means of the implementation of a bodily “dual-authentication” necessitating the person to use a certain treatment or stimulus to unlock obtain to the magnetic tag.